17

2025

-

07

Preparation and performance study of epoxy-thiol high-contrast color polymer dispersed liquid crystals

Author:

Polymer Dispersed Liquid Crystal (Polymer Dispersed Liquid Crystal, PDLC) is a smart material composed of micron-sized liquid crystal droplets dispersed in a polymer matrix. Without an electric field, the liquid crystals are arranged disorderly, scattering light (hazy state); when an electric field is applied, the liquid crystals are aligned, and the material becomes transparent. This electro-optical switching characteristic makes it widely used in smart dimming glass, privacy screens, and flexible displays, with the advantages of fast response, low energy consumption, and good mechanical stability.

Recently, the Optoelectronic Technology Research Institute of Hefei University of Technology Researcher Lu Hongbo team in " Liquid Crystals and Displays " (ESCI, Scopus indexed, Chinese core journal) 2025, Issue 7, titled " Epoxy - Preparation and Properties of High-Contrast Color Polymer Dispersed Liquid Crystals Based on Thiol " research article, was selected as the cover article of the issue. This article is based on an epoxy-thiol polymer matrix, doped with anthraquinone dyes, and achieves dual optimization of PDLC optoelectronic and mechanical properties by controlling the type and concentration of dyes.

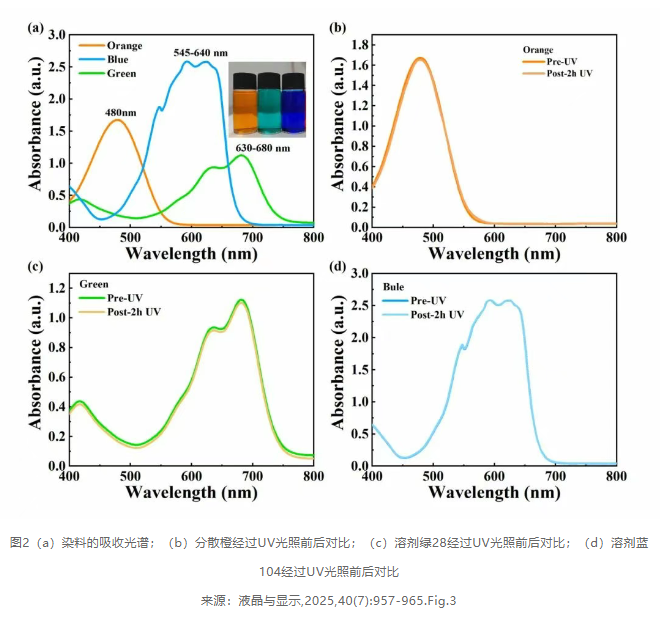

Dye Light Absorption Spectrum and Photostability Test

Traditional PDLCs are mostly white or gray, with the problem of monotonous colors, limiting their application potential in personalized design and high-value-added fields. Three anthraquinone dyes were selected to test their visible light absorption spectra, as shown in Figure 2. The three dyes exhibit characteristic absorption peaks, with the maximum absorption wavelength of Disperse Orange at 480 nm, Solvent Green 28 showing strong absorption at 630 nm ~ 680 nm, and Solvent Blue 104 having a strong absorption peak at 545 nm ~ 640 nm. At the same time, under strong light (365 nm, 30 mW/cm, 2h) irradiation, the absorption spectrum showed no significant change, exhibiting good stability. 2 The absorption spectrum showed no significant changes under strong light (365 nm, 30 mW/cm, 2h) irradiation, exhibiting good stability.

The effect of dye concentration on PDLC 's microstructure

As shown in Figures 3, 4, and 5, the effects of the concentrations of Disperse Orange, Solvent Green 28, and Solvent Blue 104 on the PDLC microstructure were characterized, respectively. All samples have a network structure. With the increase in Disperse Orange concentration, the pore size first decreases and then increases, while with the increase in Solvent Green 28 and Solvent Blue 104 content, the pore size gradually increases. This change in pore size is attributed to the strong polar groups (-NH) in the Disperse Orange molecule, which can form effective hydrogen bond interactions with the epoxy-thiol network, and the good compatibility between Disperse Orange and liquid crystals, resulting in a later phase separation time and smaller pore size; however, excessive addition will increase its absorption of ultraviolet light, leading to a decrease in the decomposition efficiency of the photogenerated base agent, and an increase in pore size. Solvent Green 28 and Solvent Blue 104 tend to absorb light, leading to a decrease in the decomposition efficiency of the photogenerated base agent and an increase in pore size. 2 The effect of dye type and concentration on

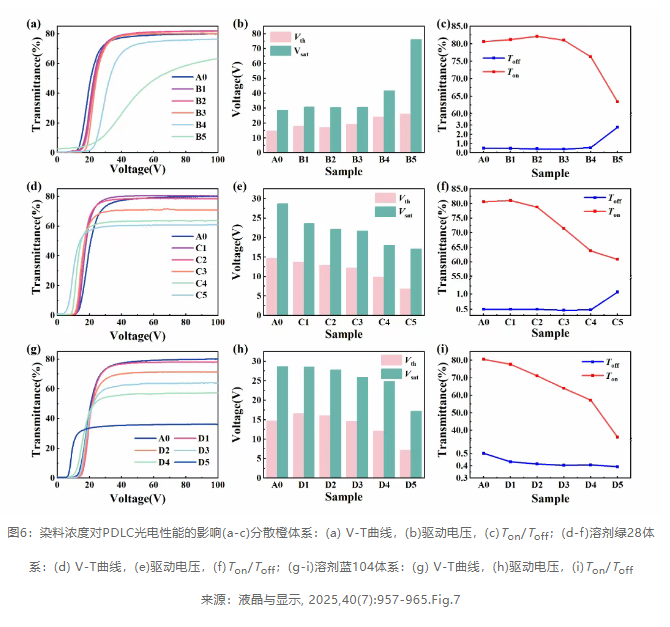

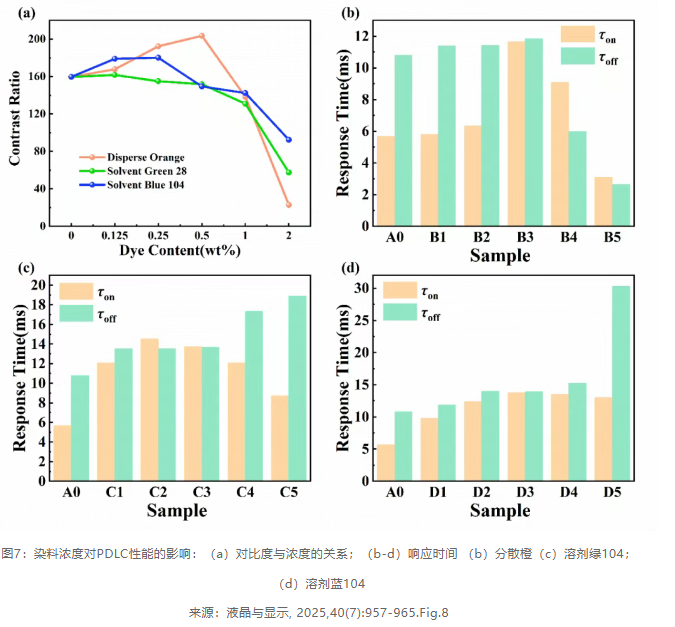

The effect of dye type and concentration on PDLC PDLC

's optoelectronic properties

The effect of dye type and concentration on PDLC The influence of dye type and concentration on the optoelectronic properties of PDLC was investigated. The introduction of Disperse Orange will lead to a gradual increase in the driving voltage of PDLC, while Solvent Green 28 and Solvent Blue 104 will reduce the driving voltage of PDLC. The addition of an appropriate amount of Disperse Orange will greatly improve the on-state transmittance of PDLC. With the addition of 0.25 wt%, the transmittance increased from 80.6% to 82.13%. However, excessive addition will reduce the transmittance due to the absorption of visible light by the dye. The addition of Solvent Blue 104 will reduce the transmittance. In addition, the addition of dyes will also affect the response time. All three dyes will cause the on-state response time to first increase and then decrease. The effect of Disperse Orange on the off-state response time is similar to that of the on-state response time, while the addition of Solvent Green 28 and Solvent Blue 104 will increase the off-state response time.

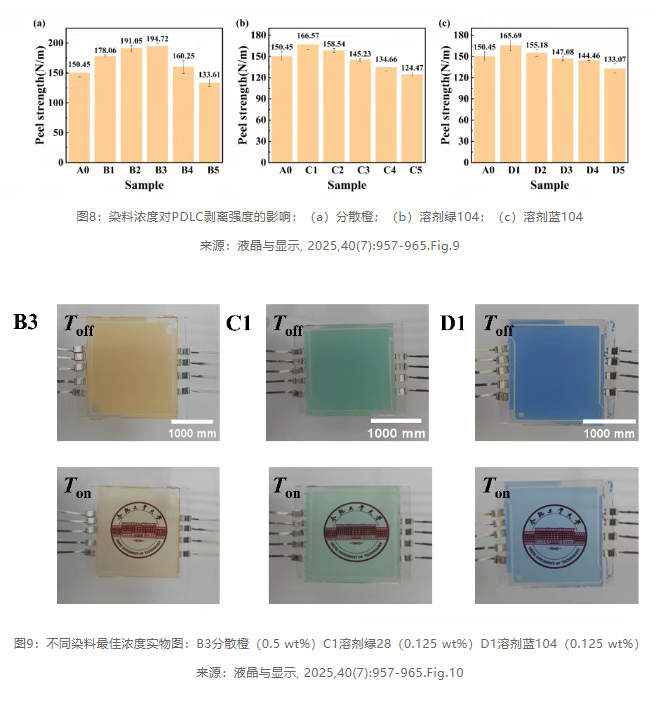

The effect of dye type and concentration on peel strength

The influence of dye type and concentration on the mechanical properties of PDLC was further investigated. The effect of the three dyes on peel strength all showed an increase followed by a decrease. The addition of Disperse Orange significantly improved the mechanical properties of PDLC, with the peel strength increasing from 150.45 N/m to 194.72 N/m with the addition of 0.5 wt%. However, Solvent Green 28 and Solvent Blue 104 only improved peel strength when added in very small amounts, and excessive amounts led to a decrease in peel strength. Good transparent and scattering states can be observed from the physical images.

Summary and Outlook This research systematically investigated the effects of three dyes, Disperse Orange, Solvent Green 28, and Solvent Blue 104, on the optoelectronic and mechanical properties of PDLC. The results show that the appropriate addition of Disperse Orange and Solvent Green 28 can optimize T on

LATEST NEWS

2025-08-20

High-order vortex beams assist super-resolution imaging

Recently, Professor Huang Zhiwei from the Department of Biomedical Engineering at the National University of Singapore led a biophotonics team in a latest study proposing that by introducing higher-order vortex beams into the minimal light flux (MINFLUX) imaging technology, the measurement accuracy of the imaging system can be significantly improved, thereby further breaking through the resolution limits of traditional optical imaging.

2025-08-20

Intrinsic Higher-Order Topological Insulators Based on Equivalent Medium Systems

Recently, Dr. Shaojie Ma, a young researcher at the Fudan University Institute of Future Information Innovation, Professor Lei Zhou from the Department of Physics, and Professor Shuang Zhang from the Department of Physics at the University of Hong Kong collaborated to achieve breakthrough progress in the field of topological state research, proving for the first time at both theoretical and experimental levels that intrinsic higher-order topological insulators (HOTI) exist in uniform electromagnetic media.

2025-08-20

Research on Non-Hermitian Properties Assisted by Orbital Angular Momentum Synthesis Dimensions

In quantum mechanics, observables usually need to satisfy Hermiticity to ensure that their eigenvalues are real numbers.

2025-08-20

Differentiable imaging unlocks full-link optimization

In the field of computational imaging, uncertainty has long constrained technological development.

2025-08-20

Reconfigurable multifunctional integrated optical computing chip

The development of artificial intelligence is driving the evolution of computing architecture towards higher performance, lower power consumption, and greater adaptability.